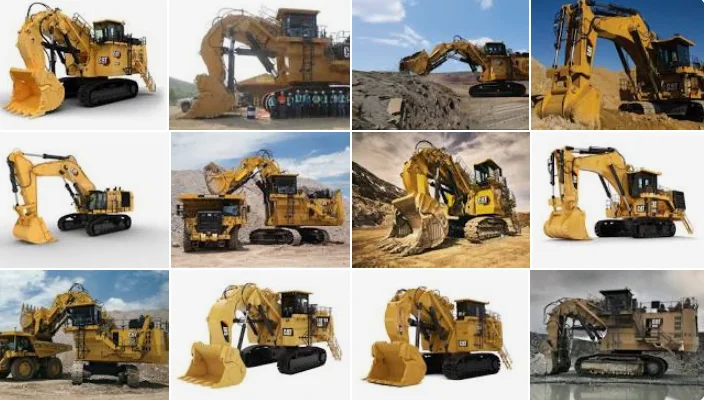

How to Pick the Right Construction Tools Components for Your Job

Choosing the ideal construction devices components for a task is an important decision that can significantly influence the job's timeline, budget plan, and general success. The procedure entails a meticulous analysis of factors such as devices compatibility, quality, integrity, cost-effectiveness, maintenance requirements, and provider reputation. Each of these components plays a critical duty in making sure that the chosen components not just go beyond the task however fulfill's demands. By thoroughly considering these elements, project managers and construction experts can make informed decisions that maximize performance and effectiveness.

Devices Compatibility

Choosing building equipment components that work with your equipment is vital for guaranteeing ideal efficiency and safety and security on your project website. When picking components, it is crucial to take into consideration the make and design of your tools to guarantee a correct fit. Utilizing incompatible components can cause breakdowns, malfunctions, and also crashes, posturing risks to both employees and the task itself.

Buying top notch, suitable components may originally appear more expensive, yet it can save you money over time by reducing downtime, repair work, and prospective safety and security risks. Focusing on devices compatibility is a proactive step that can contribute to the effectiveness and success of your building and construction job.

Quality and Dependability Assessment

When ensuring devices compatibility for your construction project, an important element to concentrate on is the assessment of top quality and reliability of the components you select. Top notch construction equipment parts are vital for the smooth operation and durability of your equipment. To evaluate the top quality of a part, look for credible brands understood for their long lasting and reputable products. Think about elements such as material quality, manufacturing standards, and any certifications the components might have.

When selecting building tools parts,Reliability is equally vital. Dependable components ensure that your equipment works effectively and minimizes the risk of unexpected failures that can postpone your task timeline and boost costs. Conduct detailed research study on the reliability of the parts you are taking into consideration by checking out evaluations, seeking recommendations from industry experts, and evaluating the manufacturer's record.

Focusing on top quality and integrity in your equipment parts selection procedure can eventually conserve you money and time by minimizing the need for regular repairs and replacements. Spend in high-quality, reputable components to ensure the success of your building task.

Cost-Effectiveness Evaluation

A thorough analysis of cost-effectiveness is important in making sure optimal resource appropriation for building equipment components. When analyzing the cost-effectiveness of building equipment components, it is critical to take into consideration not just the initial acquisition price however also elements such as long-lasting sturdiness, maintenance prices, and potential influence on project timelines. While it may be tempting to choose the least costly choice upfront, choosing low-grade components can cause frequent break downs, pricey repair services, and task delays, eventually leading to greater total costs.

To examine cost-effectiveness precisely, building and construction project supervisors ought to conduct a comprehensive analysis of the total cost of ownership for each and every devices component present. This evaluation should include not just the upfront acquisition cost yet additionally ongoing upkeep expenses, potential downtime expenses, and the anticipated lifespan of the component (Aftermarket Construction Equipment Parts). By taking an extensive view of cost-effectiveness, task supervisors can make enlightened decisions that balance in advance costs with long-lasting worth, eventually taking full advantage of the effectiveness and earnings of their building projects

Upkeep and Assistance Considerations

When choosing building and construction devices components, it is also vital to think about the schedule of support services. Choose providers that use trusted customer assistance, technical assistance, and conveniently available extra components. Quick accessibility to replacement elements can lessen downtime and other maintain the project on course.

In addition, training personnel on proper devices maintenance treatments is important. Experienced drivers can determine prospective concerns early, avoiding costly repair work and delays. our website Buying training programs can improve tools life-span and overall job efficiency. By focusing on upkeep and support considerations, task supervisors can boost tools reliability and make the most of the return on financial investment.

Vendor Track Record Evaluation

Considering the crucial function of maintenance and support in making sure the smooth procedure of building devices parts, it is crucial to completely analyze the reputation of potential distributors for ideal task performance. Supplier reputation evaluation includes evaluating variables such as reliability, item top quality, customer care, and adherence to shipment routines. A provider with a solid reputation for giving high-quality components and exceptional support can dramatically influence the overall performance and success of a building and construction project.

To evaluate a supplier's reputation, it is necessary to carry out complete study, consisting of reading reviews and testimonies from other customers, examining scores and certifications, and examining the provider's performance history in the industry. Additionally, seeking suggestions from trusted sources and market experts can supply important insights into the vendor's credibility and credibility. By picking a reliable distributor for building devices components, task managers can reduce dangers, make certain timely delivery of parts, and inevitably add to the smooth procedure of the construction job.

Conclusion

Finally, choosing the appropriate building devices parts for a project calls for careful factor to consider of variables such as compatibility, quality, cost-effectiveness, maintenance, and provider credibility. By analyzing these key aspects, job supervisors can make certain smooth operations and effective results. It is important to focus on reliability and performance in order to successfully complete construction projects within budget and timeline constraints.

Picking Full Article the ideal building and construction tools components for a task is an important choice that can dramatically impact the job's timeline, spending plan, and general success.Efficient upkeep and support factors to consider are indispensable to making certain the durability and optimum performance of building and construction equipment components throughout a project.Taking into consideration the important duty of maintenance and assistance in making certain the smooth operation of construction devices components, it is important to extensively analyze the online reputation of prospective suppliers for optimum task efficiency. By picking a trusted supplier for building and construction devices components, job managers can minimize threats, ensure prompt shipment of components, and inevitably add to the seamless operation of the construction project.

In final thought, choosing the appropriate construction devices components for a job calls for careful consideration of elements such as compatibility, quality, upkeep, vendor, and cost-effectiveness online reputation. Aftermarket Construction Equipment Parts.